Oatmeal cookies are considered not only tasty, but also a very useful product. Its main ingredient (oat flour) contains proteins that are almost completely absorbed by the human body, valuable vegetable fats, provitamin A, vitamins of group B, PP, amino acids, similar in composition to muscle protein, magnesium, phosphorus, potassium and other trace elements and minerals

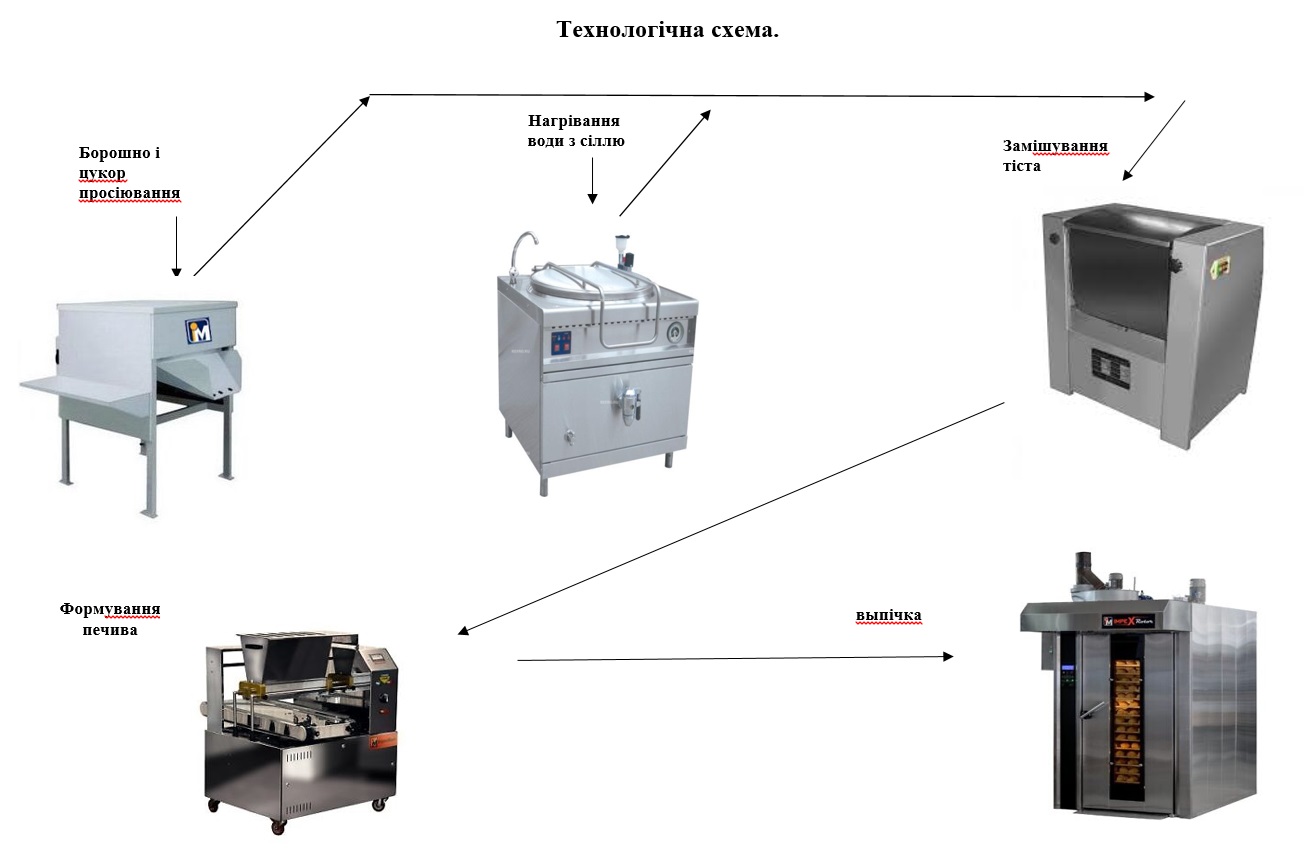

The technological process of the production of oatmeal cookies includes the following main stages:

1) dough preparation;

2) forming the dough;

3) baking;

4) cooling;

5) packaging, packaging and storage.

Sifting of flour takes place on an Impex FS-500 vibrating sieve. The emulsion is prepared in a 60-100 liter boiler. Dough for oat cookies is prepared in a 50-150 liter dough mixer. If necessary, raisins, nuts, chocolate drops, etc. are added to the dough. Dough forming is carried out on an ImpexDrop 600S deposition machine, two corrugated shafts of which push the dough through a die with a cutout of various contours, due to which the dough acquires a certain shape when squeezed. The pressed dough is cut off by a string cutting mechanism and laid out in rows on sheets. Sheets are installed on rack carts. Biscuits are baked in an ImpexRotor rotary oven at a temperature of 190°-240°C for 12-20 minutes. It is possible to bake in a tunnel oven. After baking, the cookies are cooled and packed.

| Technical characteristics of the kit | |

| Productivity, kg/h | 180 |

| Power, kW (for an electric furnace) | 60 |

| Production area, 80 square meters | 80 |

| Staff | 4 |

| Functional composition | |

| 1. Screener Impex FS-500 | 1 |

| 2. Cooking boiler | 1 |

| 3. Dough kneading machine for stiff dough | 1 |

| 4. The ImpexDrop 600S dropper machine with string sharpener | 1 |

| 5. IR/22 shelving trolley | 4 |

| 6. Impex Rotor rotary furnace (or Impex Condy tunnel furnace) | 1 |

| 7. Floor sheet 600×400 (mm) | 88 |